The overlooked secret of off-site fabrication

Off-site manufacture, pre-fabrication, modular construction, whatever it is called it has been heralded as a win:win:win solution for construction.

Through the provision of cost effective building elements and units, which require fewer deliveries to site and offers a better finish quality with less waste – what can possibly be said against the growth of this modern method of construction?

Over the last couple of years, KLH Sustainability has been asked to evaluate a variety of modular construction solutions, and although we largely agree with the rhetoric and have been able to prove significant benefits of modular construction over conventional concrete frame constructions, something isn’t adding up.

The benefits we have calculated for the modular construction of a complete building versus traditional concrete frame construction include:

- Over 45% reduction in material use.

- Over 50% reduction in waste generation. Over 40% reduction in HGV movements at the construction site.

For modular buildings, this magnitude of benefits does require the modular solution to be explored and implemented at the early stages of design so that the lightweighting of the superstructure can be translated into reduced foundations.

We have observed the improved finish quality and the quicker, safer site construction. We are also, of course very supportive of the potential creation of new jobs in construction away from the construction site, jobs that may appeal more to diverse engineers and workers who want more consistency in job location and working hours.

So where is the issue? Carbon.

In the assessments we have undertaken to date the carbon impact for the modular solution does not balance, even if the reduced site deliveries, reduced waste and reduced construction programme are taken into account.

We have calculated the additional carbon impact of modular construction of buildings to be around 20%, although for some individual building elements it may be over 100%.

So, where is all this carbon coming from?

We have found that there is significantly more structural support within modular units to cope with the stresses of transportation and lifting into position on site than is required for the structural stability of the building. This additional structural support is often integral to the units, and is fabricated from that carbon hungry material--steel.

There are some interesting solutions out there. One we observed in central London, took the form of a bespoke, reusable lifting frame for double height mansard thereby allowing the units themselves to be constructed without excess bracing.

Perhaps lightweight fibre reinforced plastic can provide some of the additional structural integrity required in pre-fabricated units? Or low-carbon timber solutions exist?

The carbon balance for modular construction may be found in the improved operational performance of modular buildings. Factory facilities should enable units to be constructed with better U-values and air-tightness and potentially reduce the energy performance gap of our buildings. However, until this is accurately assessed and quantified it is difficult to claim modular buildings can deliver a better life-cycle carbon than conventional construction techniques.

The carbon impact does not, and should not be a show-stopper for modular construction. However, it is an aspect that should not be forgotten by those developing modular construction solutions. At KLH we know that sustainability is about more than just carbon, but equally carbon is not a factor that can be ignored.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

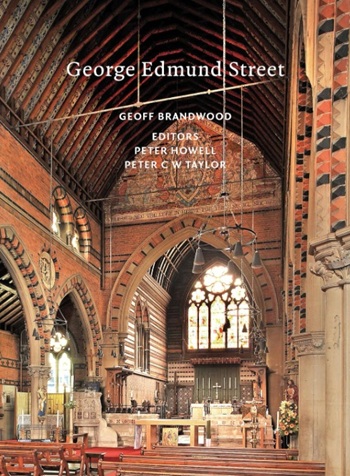

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.